What is a Solar Charge Controller

The full name of solar controller is solar charge controller. It is an automatic control device which controls solar cell array to charge the storage battery and controls storage battery to supply power to the load of solar inverter. Solar charge controller serves as the command center of photovotaic power system, which not only regulates and controls the charge and discharge of storage battery, but also controls the power output of solar cell module and storage battery according to the input demand of load.

Brief Introduction:

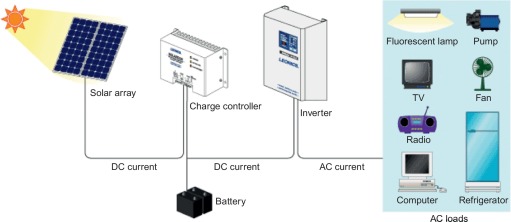

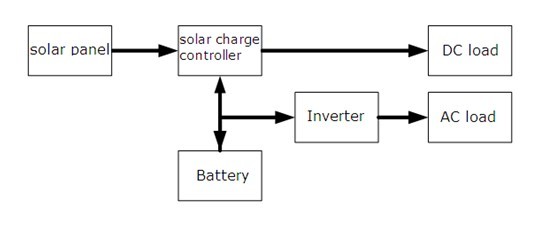

The solar controller system consists of solar panel, storage battery, solar charge controller and load.

Solar charge controller is a device which controls solar cell array to charge the storage battery and provides the load control voltage for voltage-sensitive device. Solar charge controller serves as the command center of photovotaic power system, which not only regulates and controls the charge and discharge of storage battery, but also controls the power output of solar cell module and storage battery according to the input demand of load. It is specially designed for power supply system of communication and monitoring equipment in the remote regions. The charging control voltage and load control voltage of solar charge controller are adjustable. The storage battery voltage, load voltage, solar cell array voltage, charging current and load voltage are displayed on the interface of solar charge controller.

Most solar power systems which supply the power by utilizing storage battery need a solar charge controller. One of the functions of solar charge controller is adjusting the output efficiency of solar panel to storage battery. Storage battery discharge will significantly shorten the battery lifespan and even damage the storage battery until it can not normally operate.

The solar charge controller is embedded with high-speed CPU and analog-to-digital converter with high accuracy, which is a data collection and monitoring control system. It can not only obtain the working data of photovoltaic power system in real time with a high speed, but also collect the history data of photovoltaic power system. These data is used for evaluating the design of photovoltaic power system and inspecting the quality of system components. Bseides, the solar charge controller also can transmit the serial communication data and realize centralized management and remote control of many substations.

The solar charge controller has six nominal voltage levels: 12V, 24V, 48V, 110V, 220V and 600V.

In the future, solar charge controller will be designed to be multifunctional, which combines the function of traditional controller, inverter and monitoring system.

Functions:

Most photovoltaic power system are embedded with solar charge controller in order to protect the storage battery from overcharge or overdischarge. Overcharge may result in the vaporization of battery electrolyte and then breakdown of battery, while overdischarge will shorten the lifespan of battery. Both of them will possibly damage the load. Therefore, solar charge controller is one of the core components of photovoltaic power system as well as the major component of BOS (Balance of System).

In brief, the functions of solar charge controller are as follows:

1、Efficiency Regulation;

2、Communication: (1) simple instruction; (2) protocol communicaiton;

3、Complete Protection.

Operating Principle:

The solar panel is one kind of photovoltaic equipment, which will generate current by photoelectric effect after irradiation. The major component of it is made from semiconductor. The generated current is like a curve with volatility due to the features and limitation of solar panel manufacturing materials and sunlight. If the generated current is directly charged the storage or load, it will possibly result in the damage of storage battery and load and seriouly shorten their lifespan. Therefore, the current should first go through the solar charge controller. The solar charge controller will regulate the current in a digital way with a series of dedicated chip circuits and protect the charge and discharge procedure to ensure security of operation of the battery and load. When supplying power to the load, the current should also first go through the solar charge controller and then be input to the load. The purpose of doing this is to stabilize the discharging current and avoid the discharge as well as monitor and protect the load and storage battery. The inverter is needed when using the alternating current device.

Characteristics:

1、Realize the intelligent control by utilization of monochip and dedicated software.

2、To accurately control the discharge by referring to the features of storage battery. The ultimate discharge voltage is the protection point of diacharge curve, which increase the accuracy of overdischarge control.

3、Automatic control of overcharge, overdischarge, short circuit, overload and reverse connection.

The control function will do no harm to any components and do not blew the fuse.

4、The series-type PWM charging main circuit is adopted, which reduces the voltage loss of the charging circuit by nearly half compared with the charging circuit using diodes. The charging efficiency is 3%-6% higher than that of non-PWM ones, which increases the power consumption time; over-discharge recovery improves charging, normal direct charge and automatic floating charge control methods make the lifespan of system longer; at the same time it has high-precision temperature compensation;

5、The LED luminous tube indicates the current battery llevel, allowing users to understand the usage condition;

6、The industrial-grade chips (only for industrial-grade controllers with I) are embedded in the controller, which can work in cold or hot or humid environment. At the same time, the crystal oscillator timing control is used, and the timing control is accurate;

7、The potentiometer adjustment control set point is canceled, and the E-square memory is used to record each work control point, so that the setting is digitized, and some factors which leads to the error of the control point due to the vibration of the potentiometer, temperature drift, etc., is eliminated.

8、The digital LED display and settings are used, and all settings can be completed by one-button operation. The purpose is to control the working status of the entire system, and to protect the battery from overcharge and overdischarge. In places with large temperature differences, a qualified controller should also have the function of temperature compensation. Other additional functions such as light control switch and time control switch should be embedded in the controller.

Patterns:

1、Light-operated pattern: When there is no sunlight, the solar charge controller will put off ten minutes to get started and turn on the load based on the setting parameters. When there is sunlight, the solar charge controller will put off ten miuntes to turn off the output and then the load will stop working.

2、Light-operated and time-operated pattern: The start-up procedure is the same as light-operated pattern's. When the load has worked for the setting time, it will turn off. The setting can be one to fourteen hours.

3、Manual pattern: Users can press the button to turn on or turn off the load anytime. This pattern is applied to some special conditions such as debugging.

4、Debugging pattern: This pattern is applied to testing the installation of system. The load will be turned off when there is optical signal. Similarly, the load will be turned on when there is no optical signal.

5、Long-time opening pattern: The load keeps outputting. This pattern is applied to 24 hours' power supply.

Classification

The main solar charge controllers in the market include general solar charge controller, PWM solar charge controller and MPPT solar charge controller.

General solar charge controller is the first generation technology product. It works by directly connecting the output port of solar panel to the battery port and starting charging. When the storage battery is full charged, it will interrupt the charging current. However, it is difficult to fully charge the storage battery due to the internal resistance. Therefore, the solar panel can not be made full use. The charge conversion efficiency of this kind of product is 70 percent to 76 percent so it has withdrawn from the market.

PWM solar charge controller is the second generation technology product, which has obtained the most market share at present. The operating principle is PWM module. It is more excellent than the general solar charge controller in working out the problem of not fully charging the battery. The charge conversion efficiency is 75 percent to 80 percent. However, the solar panel also can not be made full use.

MPPT solar charge controller is the third generation technology product as well as the most highest level solar charge controller. A MPPT solar charge controller is the charge controller embedded with MPPT algorithm, which is the upgraded product of PWM solar charge controller. MPPT solar charge controller can detect the voltage and current of solar panel in real time and continually track the maximum power point in order to reach the maximum efficiency for charging the storage battery. The MPPT tracking efficiency is 99 percent and the generating efficiency of the whole system is up to 97 percent. The battery is managed and protected well. The charging modes are divided into MPPT charge, constant voltage equalizaing charge and constant voltage floating charge. With the technical progress and energy conversation, MPPT solar charge controller will definitely replace PWM solar charge controller.

Functions:

1、Overcharge Protection: When the charge voltage is higher than protection voltage, the charge for storage battery will be stopped. After that, when the voltage reduces to the maintenance voltage, the storage battery will be in floating charge. When the voltage is lower than the recovery voltage, the storage battery will be in equalizing charge.

2、Overdischarge Protection: When the storage battery voltage is lower than protection voltage, the controller will close down to protect the storage battery from damage. The controller will supply the power automaticly when the storage battery charge again.

3、Load Overcurrent and Short-circuit Protection: When the load current is stronger than 10A or short-circuit happens, the fuse will be blown and then be replaced.

4、Overvoltage Protection: When the voltage is too high, the controller will close down to prevent the appliances from damage.

5、Reverse Charge Protection: Using the Schottky Diode can prevent storage battery charging the solar panel.

6、Lightning Protection: Piezoresistor can protect the controller from lightning.

7、Solar Panel Reverse Connection Protection: The positive electrode and negative electrode are connected with wrong side. It can be used after correct.

8、Storage Battery Reverse Connection Protection: The positive electrode and negative electrode are connected with wrong side and the fuse is blown. It can be used after replacing.

9、Storage Battery Open Circuit Protection: When there is open circuit in the storage battery, the controller will restrict the voltage of load to prevent the load from damage when the solar panel can normally charge. If the solar panel is not charging or at night, the controller will not work because of lack of power.

10、Temperature Compensation: The controller will regulate the battery temperature and charge and discharge to make sure that the battery is in its ideal condition.

11、Self-inspection: The controller will inspect itself when it is influenced by natural factor or wrong manual operation. This function can save time.

12、Recovery Time: It is designed for overcharge or overdischarge.

13、Light-operated: When the surrounding environment is bright enough, the controller will close down and stop outputting of load. When the surrounding environment is dark, the controller will start up the load.

Installation Notice:

1、Open the package and fix the solar charge controller on a proper place. (Please aviod fixing the controller on somewhere with direct sunlight or humid place.)

2、First, connect to the battery lead (in order to prevent errors in the automatic identification function), and wait for the controller to complete the recognition process (after the battery power displayed on the interface of the level indicator), then connect to the solar panel lead, and finally connect the load line when the load is turned off.

3、For the sake of safety, do not use the overload or over-sized solar panel.

4、When it is charging, dismantle the solar panel and pay attention to the charging current.

5、Pay attention to the positive electrode and negative electrode of battery.

Common Fault and Handling:

1、The load cannot work.

(1) The controller is light-operated in the daytime.

(2) The battery is of low power.

(3) Whether the connection is right.

(4) Disconnect all the wires and repeat the installation and then make controller recognize again.

2、The controller cannot work after several days.

(1) The connection of wiring of solar cell is wrong.

(2) The solar cell is not connected well.

3、The light-operated pattern cannot work.

(1) The connection of wiring of solar cell is wrong.

(2) This function is not be set. Please reset again.

4、The controller works as soon as it turns on, but it cannot realize light control and time control.

(1) This function is not be set. Please reset again.

(2) High intensity of sunlight.

5、The work indicator light blinks continuously.

Overload or short-circuit of the load.

Protection Mode:

1、Direct Charge Protection Voltage:

Direct charge is one kind of quick charge, which means charging the storage battery with strong current at a relatively high voltage when the voltage of storage battery is low. When the voltage of storage battery is higher than overvoltage protection value, the direct charge will be stopped. Otherwise, it will result in overcharge and do harm to the storage battery.

2、Equalizing Charge Control Voltage:

After the direct charge, the voltage of storage battery will drop spontaneously. When it drops to "recovery value", the storage battery will be in equalizing charge. The reason why we design equalizing charge is that the voltage of some batteries will be relatively low after direct charge. To unify the voltage of all batteries, the batteries will be charged with moderate current at high voltage. That is called "equalizing charge." The time for equalizing charge should not be too long. Otherwise, it will do harm to the battery. Genarally, the equalizing charge lasts for ten to twenty minutes. Equalizing charge is not suitable for those systems which are embedded with one or two storage batteries. Therefore, the charge controller for streetlight will not be in equalizing charge.

3、Floating Charge Protection Volatge:

After the floating charge, the voltage of storage battery will drop spontaneously. When it drops "maintenance value", the storage battery will be in floating charge, which means charging with weak current to avoid battery temperature from rising continuously. The floating charge is good for storage battery because battery temperature has a strong impact on charge and discharge. PWM charging method is designed for stablize the storage battery voltage. It is a scientific charging method that reduces the storage battery charging current by modulating the pulse width. To be specific, when the SOC of storage battery is higher than eighty percent, the charging current should be reduced. Otherwise, the controller will release several kinds of gases because of overcharge.

4、Overdischarge Protection Termination Voltage: The national standard requests that the storage battery discharge voltage should not be lower than this value. For the sake of safety, the overdischarge protection voltage point of the 12V battery is generally added 0.3v as temperature compensation or the zero-point drift correction of the control circuit, so that the overdischarge protection voltage point of the 12V battery is 11.10V, then the overdischarge protection voltage point of the 24V system is 22.20V.

Related Knowledge:

Protection Voltage:

Some customers found that the solar streetlight can not work for several days after continuous rainy days. However, the storage battery voltage, solar charge controller and streelight are detected normal. This problem used to make project contractor confused. Actually, the streetlight can not work for several days because the low-voltage protection value is set too high and then the recovery time will be longer.

Output Current:

The LED will not work unless the current is restricted. Generally, the LED lights connect with a driving power source in order to restrict the current of LED lights. But this driving power source will take up ten to twenty percent of LED light total power. For example, the total power of a LED light is 42W theoretically. However, the total power will be 46W to 50W in fact when connecting with a driving power source. When calculating the solar panel power and storage battery capacity, we are supposed to consider the power loss caused by the driving power source. Besides, the driving power source may lead to breakdown. Industrial controller restricts the current through the software, which is of high stablity and lower power loss.

Output Time:

The general controller can only be set to close down after turning on the light for four or eight hours, which can not satisfy the need of most customers. However, the output time of industrial controller can be divided into three stages which can be set randomly. According to the different environment, the controller at every stage can be set to be closed. For example, there is no one in factory or scenic area at the late night. Therefore, the second stage or third stage should be closed down in order to reduce the cost.

Output Power:

Among solar lights, LED lights are the most suitable for achieving different output power through pulse width modulation. When limiting the pulse width or the current, the controller will adjust the duty cycle of the entire output of the LED light. For example, a single 35W LED lights can be discharged at night, and the power will be adjusted at late night and in the early morning. For example, adjust the power to 15W in the middle of the night and 25W in the early morning, and then lock the current, so that it can meet the need of lighting all night, and save the cost of solar panels and storage batteries. It has proved that the LED light with pulse width modulation method generates much less heat, which can extend the lifespan of the LED.

In order to save power at night, some lamp factories make the interior of LED lights into two power sources, and turn off one power source at night to reduce half the output power. However, it has proved that this method will only result in light attenuation, inconsistent brightness, or advanced damage to one light source.

Cable Loss Compensation:

Cable loss compensation is very important in the low-voltage system. The cable loss is relatively high because of low voltage. Therefore, if there is no cable loss compensation, the output voltage will be lower than the input voltage, which will result in advanced low voltage protection and low untilization rate of storage battery capacity. It's worth noting that we should not use cables which is too tenuous or too long when using the low voltage system.

Heat Dissipation:

The heat dissipation is not be considered into the design of controllers for the purpose of reducing the cost. When the load current or charge current is strong, the heat and internal resistance of controller will increase, which will lower the charge efficiency. Besides, the outdoor temperature is quite high in the summer. So, high-quality device for heat dissipation is a necessory component of controller.

Charge Pattern:

The charge pattern of conventional solar charge controller is divided into three stages, which is constant current stage, constant voltage stage and floating charge stage. The energy of the mains power grid is infinite. If the constant current charging is not carried out, the storage battery will be damaged due to overcharge. However, the power of solar panel of solar streetlight is limited. It is unscientific to continuously use the constant current charging method. If the solar panel current is stronger than the restricted current at the first charging stage, it will lead to the reduction of charging efficiency. MCT charging method is to track the maximum current of the solar panel without causing loss. It will detect the battery voltage and calculate the temperature compensation value. When the battery voltage is close to the peak value, the pulse-type weak current charging method is carried out. It can not only fully charge the battery but also prevents overcharge.